PVD Coating Systems

Welcome to your expert for PVD coating systems

In 1983, the current voestalpine eifeler group was successfully founded in Düsseldorf, Germany. PVD plant construction was started as early as 1990.

The result is impressive: 24 worldwide locations have been equipped with PVD coating systems from voestalpine eifeler Vacotec GmbH to date. We are very proud of this figure, because our toughest critics are in-house and demand the best advice and the highest quality in order to ensure economic success.

At the same time, we can look back on a large number of worldwide customers who value our extensive consulting services and our technologically sophisticated PVD systems.

Benefit from our know-how in the field of PVD coating. Our PVD coatings are developed in our in-house research and development department and tailored to market and customer needs. A circumstance that benefits your individual needs, since we ourselves are active as a PVD coating service provider and thus know what is needed on the market.

Intensive cooperation with universities and research institutes ensures, among other things, that we have access to a large number of competent application engineers and developers who research and develop new PVD coatings at five of our own PVD facilities alone. This competence is rounded off by comprehensive analytics for layer and surface diagnostics.

Take the opportunity below to get an overview of our extensive product and service portfolio.

An inquiry is worthwhile guaranteed

- Robust and easy to maintain PVD systems

- Easy handling of the systems

- Technologically sophisticated product range

- PVD coatings for highest requirements in all segments

- Customized recipe solutions possible

- Worldwide service

- Good price / performance ratio

Your industry

You have one goal: By investing in a new coating center or another PVD system, you want to secure the long-term economic success of your company. An investment must be well considered and tailored to your individual needs. A PVD system is not a substitute good, which is set up identically for every industry.

Our technical consultants start with your initial situation, see your challenge as theirs and advise you holistically – from the sensible integration of the PVD system in your production, to the necessary peripheral equipment, which you can purchase directly from us, to the service and maintenance contract.

Below you will find an initial overview of industries for which we already offer individual solutions from our portfolio.

- Tool manufacturer

- Coating service provider

- Scientific institutions

- Mints and minting plants

- Medical technology

- Aerospace

- Decorative

- Components

You can´t find your industry? No problem, we will find individual solutions for your application.

Convincing through technology

- DUPLEX technology to increase the surface hardness of the substrate material and thus higher production efficiency

- SPCS technology for minimizing layer defects (droplets), resulting in smoother layer surfaces compared to conventional ARC layers

- Target shutter system to avoid contamination of the targets, thus increasing the efficiency of the processes

- Fast Cooling System to increase the cooling rate to generate shorter process times and maximize utilization rate

- Split frame for flexible installation of the PVD system in tight production facilities

Convincing through technology

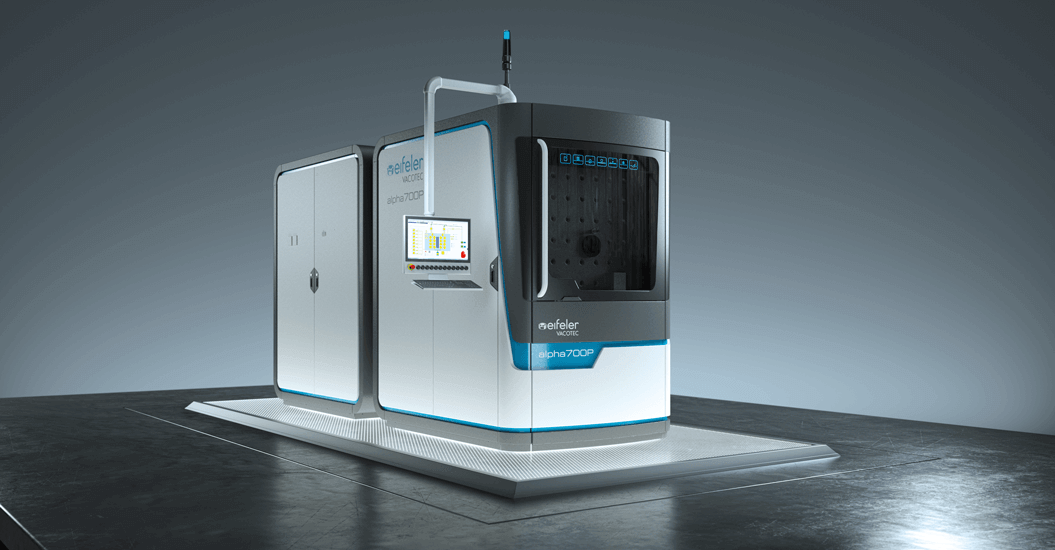

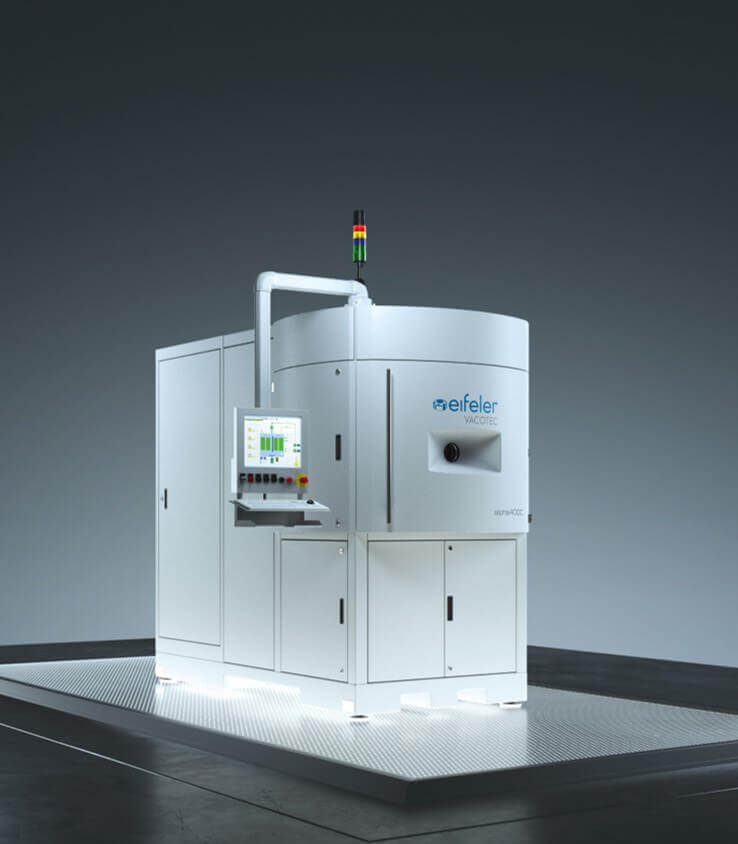

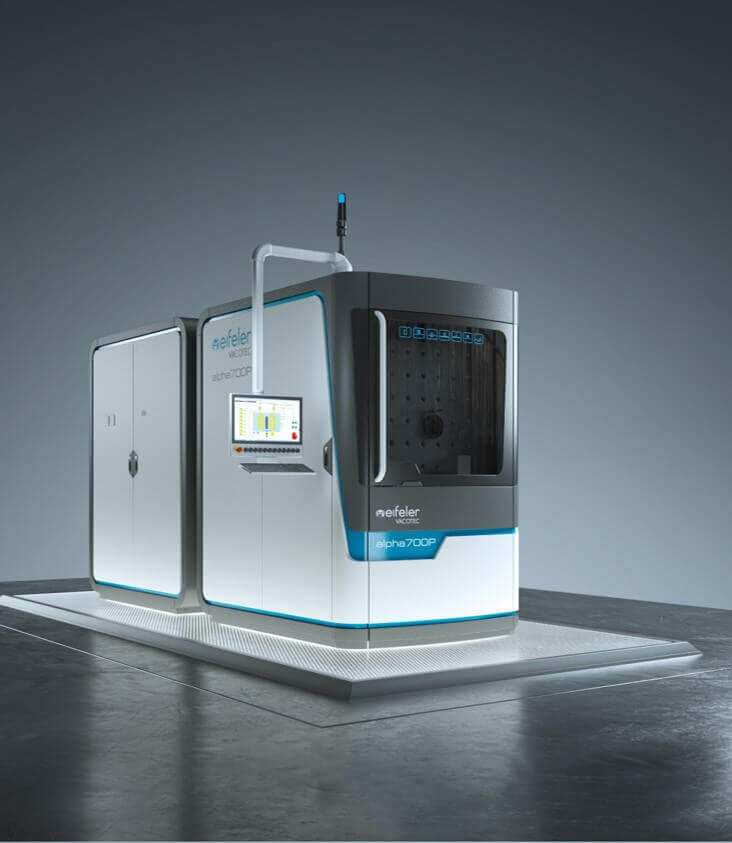

Our flexible PVD all-rounders at a glance

We design and plan our plant models based on your individual needs. In recent years, we have designed and continuously developed a large number of different systems. Flexibility is an essential factor in PVD coating. With our subsequent PVD systems, you can expect a high degree of flexibility in the coating process.

Our efficient PVD systems at a glance

Effectiveness is another important aspect in the field of PVD coating. With our large and productive PVD systems, you can easily coat large tools, parts or components or coat large quantities in just a few batches.

PVD Coating Systems

- alpha200 pdf | 614 KB

- alpha400P pdf | 641 KB

- alpha400C pdf | 656 KB

- alpha700P pdf | 1.8 MB

- alpha900P pdf | 313 KB

- alpha1000C pdf | 634 KB