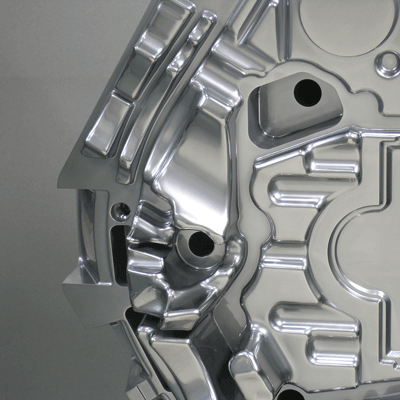

Die Casting

TIGRAL® – AlCrTiN

TIGRAL® AlCrTiN Coating

TIGRAL® – Abrasion resistance and high thermal resistivity

This layer on the basis of AlCrTiN is characterized by its high warm hardness, its oxidation stability and its abrasion resistance. These properties can be attributed to a nano-structure that minimizes crack propagation especially in case of shear loading within the coating.

Sheet-metal work:

In case of warm forming of sheets or solid material, TIGRAL® AlCrTiN coating distinguishes itself particularly. Here the excellent warm hardness, as well as the oxidation stability comes to the fore, however, also the increased resistance with respect to the propagation of microcracks in the layer which often represents a significant failure criterion in case of such applications. Also in the area of the cold forming of sheets TIGRAL® coatings indicated their suitability: High abrasion resistance with low tendency to cold welding with steel.

Machining:

Also with dry machining, the special properties of TIGRAL® (aluminum chromium titanium nitride) coating have proved themselves. In case of interrupted cutting, the range to higher contact temperatures between chip and rake face can be opened through this coating. However, also with reaming in particular of medium-alloy and higher-alloy steels, is the TIGRAL® coating very usefully usable.

Application Areas

Technical Information

| Hardness: | 3.300 ± 300 HV |

| Maximum application temperature: | 900°C / 1.652°F |

| Coeff. of friction against steel: | 0.6 |

| Layer thickness: | 3-5 µm |

| Color: | dark-gray |