Stamping & Forming

Dumatic

DUMATIC® Coating

DUMATIC® – titanium carbide – Highest levels of hardness and abrasion resistance for forming applications

Coating structure

This coating combines the advantages of Duplex-TiCN and FORMATIC®. The new DUMATIC® coating is always manufactured as a Duplex version, therefore with a plasma diffusion process of the base material. DUMATIC® is a structured multi-layer design with high content of TiC (approx. 4000 HV! ). The uppermost layer is developed as slide-favorable and colored sealing coat. Contact us to learn more about this extraordinary PVD coating.

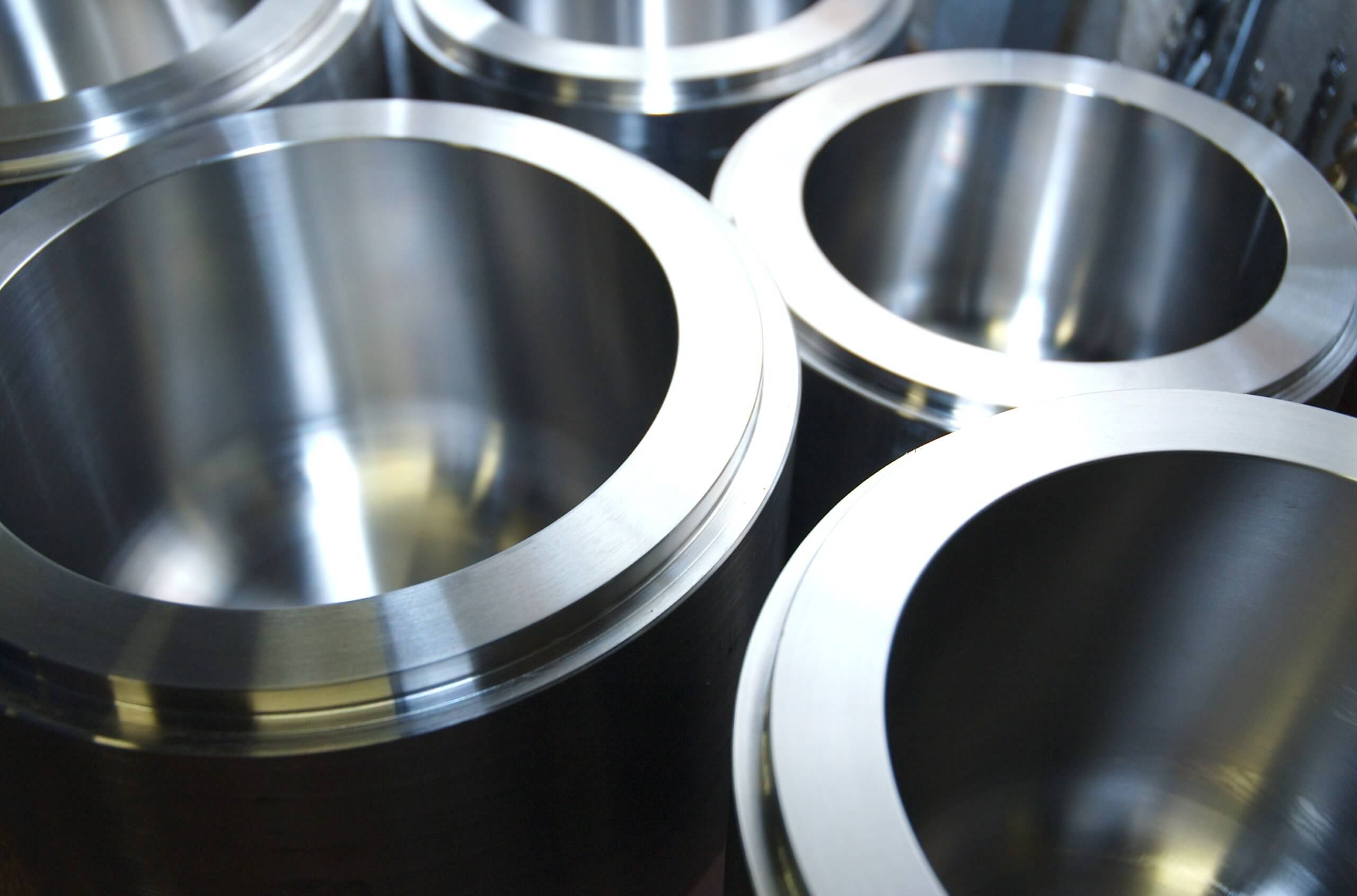

The dies and punches used in stamping, forming, and blanking operations can greatly benefit from the DUMATIC® coating. This coating provides superior wear resistance and a significant reduction in material adhesion throughout the process. With tools coated with DUMATIC®, customers experience the following benefits:

Benefits of using DUMATIC®:

- Increased tool durability: The DUMATIC® coating improves the wear resistance of dies and punches, extending their lifespan and reducing the need for frequent replacement.

- Reduced downtime: By reducing material adhesion and abrasion, DUMATIC® helps prevent blockages and jams during the stamping and forming process, resulting in less machinery downtime and increased operational efficiency.

- Improved product quality: The reduction in material adhesion provided by DUMATIC® contributes to greater precision and consistency in stamped and formed parts, resulting in higher-quality end products with fewer defects.

Due to its relatively low oxidation stability, DUMATIC® is not suitable for high-temperature applications.

Application Areas

In numbers:

| Hardness: | 3.700 ± 500 HV |

| Maximum application temperature: | 400°C / 750°F |

| Coefficient of friction against steel: | 0.25 |

| Layer thickness: | 3-5 µm |

| Color: | roan |