Plastic Injection Molding

SISTRAL®

SISTRAL® PVD Coating

Our new nano-structured high performance layer

SISTRAL® – on the basis of our very successful more advanced EXXTRAL®,

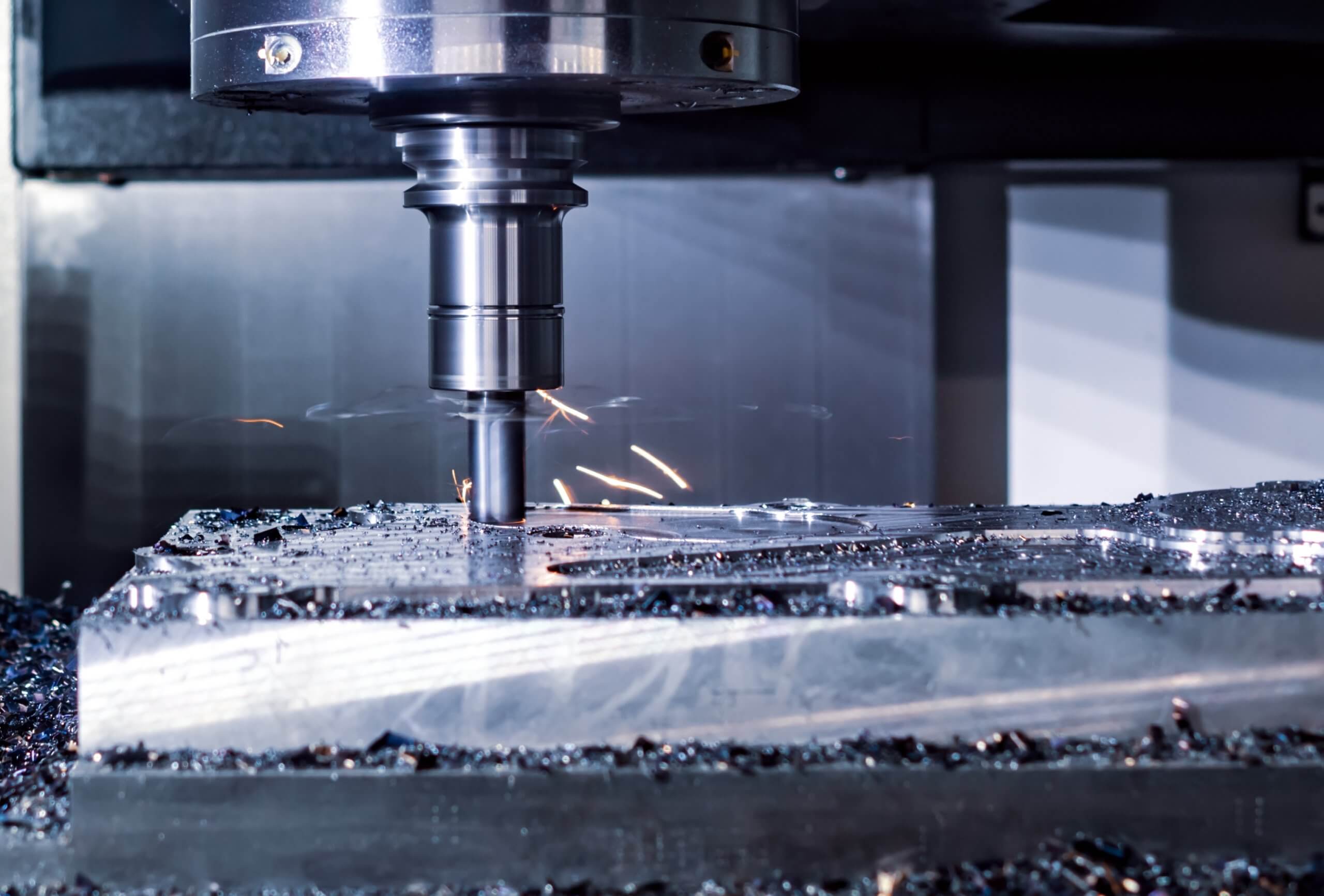

• for even higher requirements in case of machining, in the foreground

• for the dry high-speed processing of hardened materials (>54 HRC).

SISTRAL® PVD Coating, which is also anthracite colored, is characterized by a very high hardness that still protects against wear also at high temperatures, and an exceptional oxidation stability.

Applications:

Cutting tasks (milling, drilling, turning, sawing, etc. ) under in-service conditions, where other layers reach the limits of thermal and mechanical loading capacity. High-performance machining (HSC) of very abrasive or hard materials (steel > 54 HRC) in dry high-speed application. SISTRAL is also an excellent coating for reaming applications.

Deposition technology:

SISTRAL® is deposited in latest eifeler PVD ARC systems. With temperatures of approx. 450° C high-performance cemented carbides are mainly coated. The coating of tool steels and HSS is also possible!

Application Areas

In numbers:

| Material: | Aluminum-titanium nitride (with additives), AlTiN (nano-structured) |

| Microhardness HV 0.05: | 3400 ± 500 |

| Coefficient of friction against steel 100Cr6: | 0.7 |

| Layer Thickness [µm]: | 2 – 4 [1] |

| Maximum application temperature: | 900° C / 1650° F |

| Color: | Anthracite |

| General characteristic: | Extremely high oxidation and wear resistance, high warm hardness |

| Preferred applications: | Machining under extreme conditions; high-performance cutting of very abrasive or hard materials (steel > 54 HRc); Inconel machining |