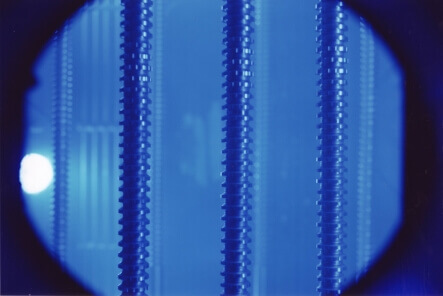

PVD Technology

Physical vapor deposition technology (PVD) is used to describe any of a variety of methods to deposit thin films by the condensation of a vaporized form of material onto various surfaces. The metallic elements of the layers consist of titanium, chrome and aluminum, make a connection to nitrogen and carbon, under impact of a plasma and temperatures of 200 °C to 500 °C. They provide a strong ceramic in this way. The hardness of generated layers are in a range of 1000 to 3800 HV, the coating thickness is between 1 to 10 µm, depending of use.

For 30 years voestalpine eifeler group has been a specialist in forming tool coatings and PVD coating technology. We can help to choose suitable tool-steel and give advice in engineering and tool handling.