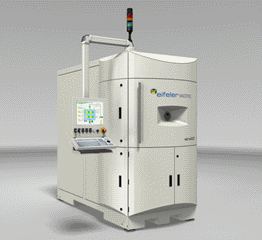

alpha 200

Alpha 200 PVD Coating System

General characteristics

Our smallest standard system can do everything that the large systems can do: Same evaporator concept, same layer portfolio.

As a result of the smaller usable volume, reaction time with the alpha 200 PVD coating system

can be even faster: Smaller batch volume, high level of flexibility and short process times.

In this case, the easy-to-use visualization and a computer-aided process-control guarantee a simple operation of the system and a reproducible and high-quality standard.

Area of application

The alpha 200 is planned for employment in the following companies:

- In smaller coating productions for short reaction times

- In experimental departments of tool manufacturers as an R&D system

- In research departments of universities as a laboratory system

- In production lines of original part manufacturers (OEM) as an extension to high-production-rate systems

Technology

The process technology makes possible the deposition of mono layers and multiple layers, as well as a nano-structured layer system. The equipment with SPCS is optional. As a result of this, the following layers can be deposited reliably with high quality and at low cost:

- All standard layers such as TiN, TiCN, CrN, ZrN, CrCN, ZrCN

- Modern hard wear resistant coatings such as EXXTRAL®, EXXTRAL® silver, EXXTRAL®-plus, TOPMATIC, VARIANTIC® and SUPRAL

- Nano-structured, high-performance coatings such as TIGRAL, CROSAL® and SISTRAL®.

Technique

With the development of this compact machine, a high place value was set on the utilization of high-quality components. Constructionally-similar components are often used in this case extending over all machine types. The construction design of these components, which is rugged and suitable for industrial use, lowers not only the maintenance and spare part requirement, but also reduces the probability of an outage of the system.

Batching system

The easy-to-use batching system allows the operator an optimal and reliable operating mode. voestalpine eifeler Vacotec offers a comprehensive program of batching means which can be used in all machines. Regardless of whether it involves cover sleeves for shaft tools, plug holders or rotation cups: We have a catalogue which is based on more than 25 years of experience in job coating.

Maintenance and service

Low maintenance requirement and good access to all important components are only two of the typical characteristics of this innovative system design. Access to the data is possible during the entire process, as is access to the remote control for online maintenance.

Technical data

| Substrate | |

| Material: | tool steel, HSS, cemented carbide, … |

| Tool diameter: | Triple rotation max. Ø 40 mm |

| Single rotation max. Ø 350 mm | |

| Tool height: | max. 325 mm |

| Load: | max. 250 kg |

| Coating chamber | |

| Dimensions: | 580 x 600 x 580 mm (L x W x H) |

| Vacuum system | |

| Rotary vane pump: | 65 m³/h |

| Turbomolecular pump: | 685 l/s |

| Radiant heater | |

| Power: | 2 x 5 kW |

| Substrate temperature: | up to 500 °C |

| Bias power supply | |

| Power: | 10 kW |

| Voltage: | max. 1000 V DC /pulsed DC |

| Arc-evaporator | |

| Number: | 8 pieces |

| Cathode diameter: | Ø 100 mm |

| Current per cathode : | max. 125 A |

| Power requirements | |

| Mains: | TN-S 400/230 VAC / +-10% / 50 or 60 Hz |

| Power: | 35 kVA |