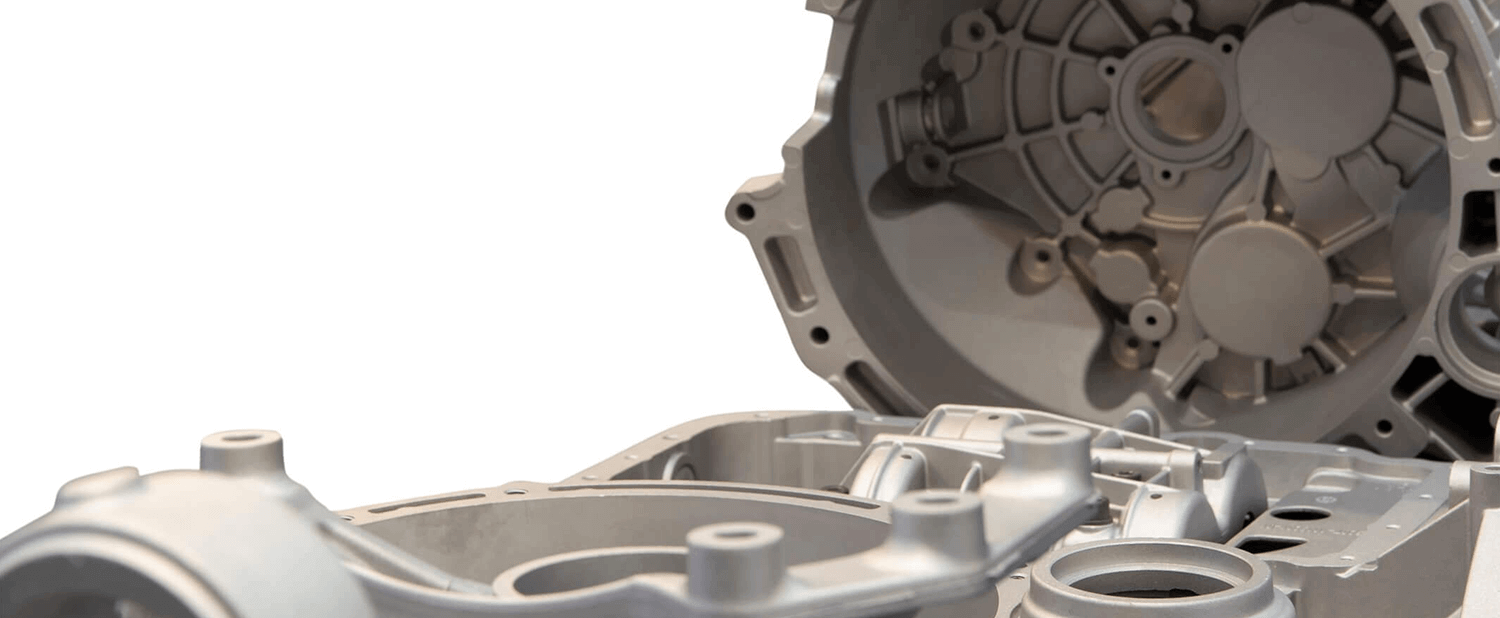

Die Casting

PVD Coatings for Die Casting

Capable of producing complex shapes with superior strength, the die casting process is used to manufacture everything from engine parts to railway components. It involves turning molten metal into specific forms using extreme temperatures and compressive forces, but excessive degradation can be an undesirable byproduct.

We support our customers to minimize the wear, cracking, and corrosion of tooling on their casting lines. voestalpine eifeler Group is a leading provider of advanced Physical Vapor Deposition coatings (PVD coatings) shown to boost tooling lifespan and reduce the likelihood of irregularities that can disrupt productivity.

The Perfect Coating for Increased Tools Lifespan

Needed to be strong and precise, tooling for die casting is a significant investment. Common issues such as thermal fatigue, gross cracking, indentation, corrosion or erosion can reduce product quality and productivity. A PVD coating from voestalpine eifeler Group has been shown to greatly improve production length, reliability, and part quality while curbing machine downtime and maintenance costs.

Using a patented, two-stage process, tooling surfaces are hardened by Plasma and Ion Nitriding before a mono-layered PVD coating is applied. Referred to as Duplex-TIGRAL®, this treatment creates a hard, wear-resistant barrier that reduces the effects of tooling surface soldering, erosion, and wear.

Benefits of Duplex – TIGRAL® for Cracking Prevention

Incorporating our Duplex – TIGRAL® into your die casting operation offers a variety of advantages. Examples include:

-Better Production Efficiency

-Longer Tool Lifespan

-Lower Scrap Rates

-Greater Precision

-Lower Overall Costs

Let’s Get Started Today

Whether you’re looking for soldering reducing coatings, erosion resistant surface coatings, or something else altogether, Duplex – TIGRAL® has you covered.

We’re happy to help you to get the optimal die casting process. Just tell us about your operation and goals as well as the issues you’re facing. Our team who visits you specializes in providing personalized and reliable advice, always thinking in satisfying your needs.

Contact us to learn more about our Duplex – TIGRAL® for die casting processes.

Select the right Coating and Tool Steel for best result

By applying a PVD/DLC coating, tool life can be increased. This improves production length, reliability and part quality as well as reduces downtime and maintenance costs. By combining a coating with the most suitable tool steel, correctly machined and heat treated, even greater benefits and savings can be achieved. Through our close cooperation with tool makers, material suppliers and our additive manufacturing providers, eifeler is uniquely positioned to support you throughout the process and increase your total tooling performance.

General about Die Casting

In die casting, melts of different alloys are injected with pressure into a die set and then solidified. Depending on the melt alloy, the dies are subjected to different high thermal and mechanical stresses.

Typical die failures

Die casting dies are exposed to severe thermal and mechanical cyclic loading, which puts high demands on the die material. Thus, there are some phenomena, which restrict die life.

- Thermal fatigue cracking: The most common die failure in die casting is thermal fatigue cracking. During the die casting process the dies are subjected to alternate heating and cooling leading to high thermal stresses. This gives rise to severe strains in the surface layer of the die, gradually leading to thermal fatigue cracks (known as “heat checking”). Factors influencing thermal fatigue are basic material properties, design, die manufacturing and heat treatment (surface treatment), production parameters and maintenance.

- Gross cracking: Gross cracking is a temporarily thermal and/or mechanical over loading of the die. It may lead to large cracks and even total failure of the die. Fractures influencing gross cracking are basic material properties, design, die manufacturing and heat treatment, production parameters and maintenance.

- Indentation: Indentation in the parting lines or cavity surface are a matter of production parameters and basic die material properties.

- Corrosion: In cases where the cavity surface lacks a protective layer, the cast metal will diffuse into the die surface. At the same time, alloying elements within the die, will diffuse from the die surface into the cast metal. These processes can create both dissolution of the steel and intermetallic compounds between the cast metal and the die surface. In cases where severe formation of intermetallic compounds occurs, the cast metal will solder to the die surface. Factors influencing corrosion are production parameters, die design and surface treatment.

- Erosion: This is a form of hot mechanical wear on the die surface, often in and near the gating area. Erosion depends to a high degree on production parameters and die design. Most commonly a combination of corrosion and erosion damages occur on the die surface.

Die material properties

For the best die performance, the following basic die steel values and properties should be high and good:

- Hot yield strength

- Temper resistance

- Creep strength

- Ductility

- Toughness

For more information on reduce soldering in die casting contact us.

Find your nearest eifeler site

Downloads