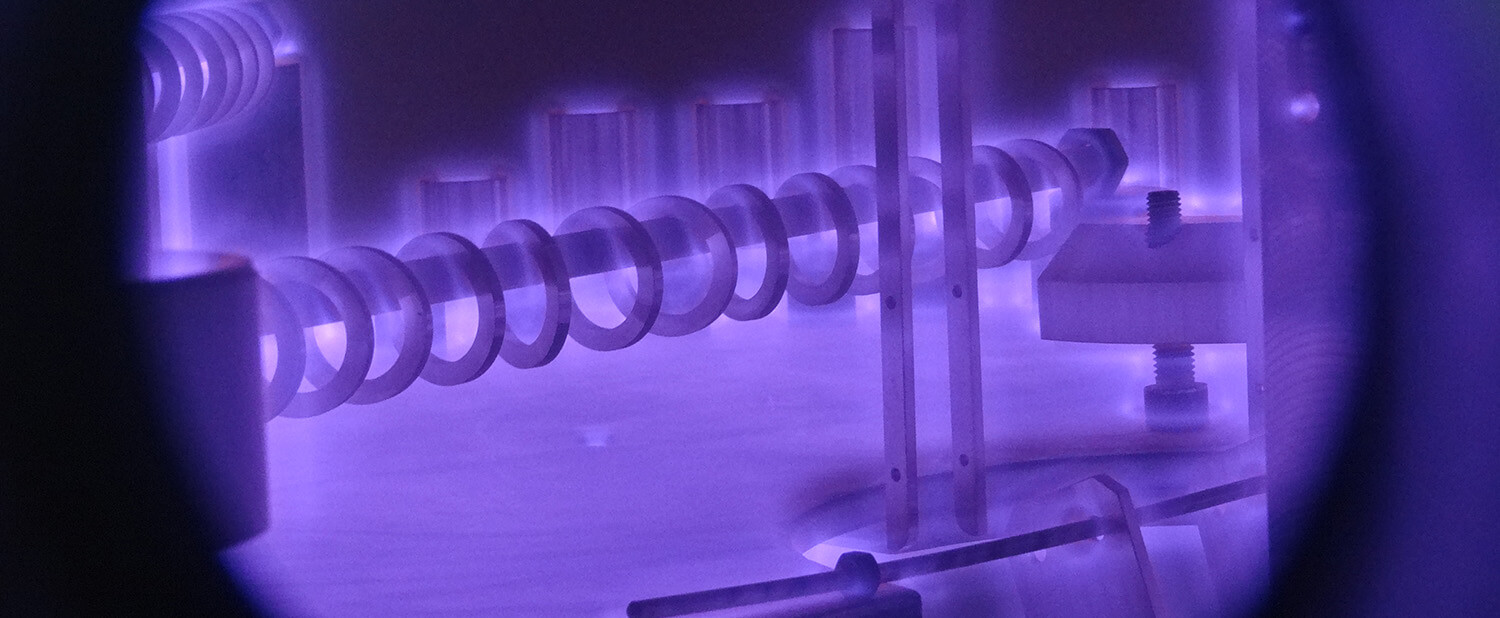

Plasma treatment

Plasma treatment is also offered by us for the production of hard and corrosion-resistant surfaces. The one prerequisite is a high technical standard of the machines.

The other factors are expertise, training and experience of the employees, in order to generate the best quality.

We can offer you the following plasma treatments:

Plasma nitriding is a modern and environmentally-friendly nitriding and nitro-carburizing process, adopted to steel quality and surface.

Process-technical features

- Nitriding and nitro-carburizing of an alloyed steel, cast iron, sintered and special materials

- Reproducible, hard and ductile, nitriding layer structure

- Large treatment temperature range of 400 – 600°C

- Comparably short processing cycles

- Forced depassivation, also of high-alloy steels

- Partial nitriding of the workpieces

- Low distortion, high preservation of dimensional accuracy

- No high-cost mechanical post-treatment

- Furnace program coordinated to component parts

- Proven in individual and series parts

- Standing and/or suspended charging

- Environmentally-friendly

Boundary layer properties

Plasma nitriding allows nitriding layers to be structured, which can be adapted to the respective component loading in an optimum manner. The forced nitriding-caused decrease of the ductility in the boundary layer is controlled during plasma nitriding, so that in spite of a hardness increase ductility also remains in the boundary layer. Specialists therefore speak of the plasma-nitriding-type hard layer ductility.

A nitriding layer consists in general of a diffusion layer and compound layer located above it, whose formation is depending on the steel quality and the processing parameters of temperature, duration and gas composition.

The compound layer primarily determines the properties of plasma nitrided component parts. The iron-nitrogen compounds Fe4N and Fe2-3N can be generated purposefully and reproducibly on the diffused layer and supporting it. They are monophase and low-pore, resist wear stressing and offer corrosion protection. Also in case of overlaid dynamic loading, these properties are maintained.

The diffusion layer underneath the compound layer can be structured with low nitride linings and to a large extent free from grain boundary nitriding, which contributes to the embrittlement of the boundary layers as it is generally known. It determines the strength characteristics of plasma-nitrided workpieces. The diffusion layer can also be generated without forming a connecting layer and finds application in certain cases.

Process advantages

Also component parts with complex geometry, bores or cylinders are provided with the plasma-nitriding-type boundary layers. The process engineering of plasma nitriding in vacuum guarantees good dimensional stability and low distortion. Stress relieve annealing is especially useful before the mechanical finishing.

With paste and solid coverings, workpieces can be plasma-nitrided partially. The vacuum processing saves the following cleaning of the plasma nitrated charge. Roughness changes are so small that a mechanical after treatment can be dispensed with. Highly polished tools, which should be slightly finished after the processing, form exceptions.

Annealing sensitive steels are plasma nitrided with comparably low treatment temperatures. High-alloy steels and special materials can also be plasma nitrided above the usual treatment temperatures.

Plasma oxidation, as an after treatment of the plasma nitriding and plasma nitro-carburizing process generates highly resistant Fe3O4 layers on the workpieces and fills possible existing pores in the connecting layer through oxide formation.

The strong-adhering oxide layers thus generated are characterized by:

- Corrosion resistance

- Improved slide characteristics and

- a black glossy surfac

Our services in plasma nitriding

MOLDADUR® is a special diffusion process of voestalpine eifeler Coating GmbH, which creates a protective layer on highly sensitive surfaces in plastic injection molding. MOLDADUR® increases the surface hardness of the tool and creates a scratch-resistant protective layer without any dimensional change, influence on surface quality, basic hardness or optical appearance. Areas of application for MOLDADUR® treatment are polished, structured and grained tools in plastic mold construction. It is also suitable for treating parts that easily wrap.

MOLDADUR®-P ist also a special plasma process, which creates a layer on highly sensitive surfaces that provides lasting protection against wear and damage. This process can be directly combined with a PVD coating.

Areas of application for MOLDADUR®-P treatment are polished, structured and grained tools in plastic mold construction. It is also suitable for treating parts that easily wrap.

In addition to the tried-and-tested MOLDADUR®-P process, there is also the MOLDADUR®-P stainless process. This is specially developed for stainless steels and protects the surfaces from wear and damage, while maintaining the corrosion resistance as far as possible.

Here you find the latest datasheet: MOLDADUR®-P stainless