DIVE INTO ANOTHER WORLD

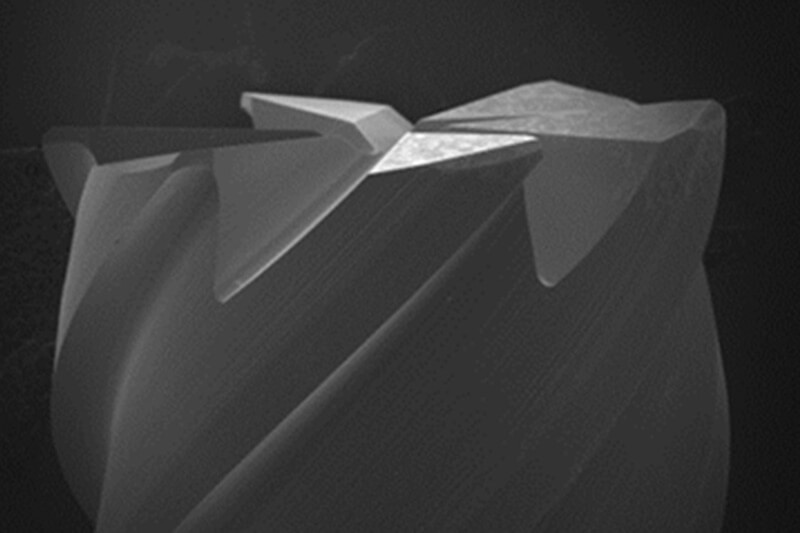

For us, everything revolves around the very small, so that great things can be created. We push the smallest building blocks of matter through a vacuum and rebuild them in an orderly fashion on tools to create extremely hard layers. This is a fundamental prerequisite for the series production of modern tools or highly stressed components.

PRECISION AND CONTROL

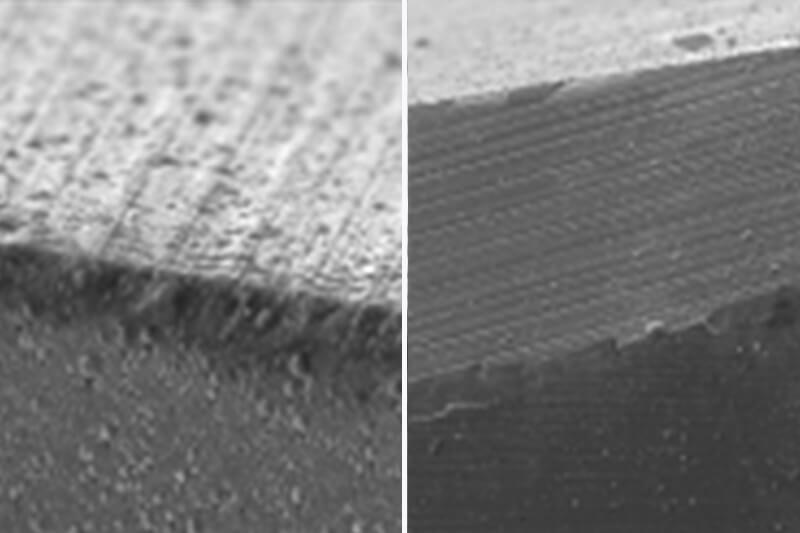

The PVD process enables the deposition of extremely thin layers with a thickness in the nanometer range up to a few micrometers. For comparison: a human hair has a diameter of 50 µm. Despite the small thickness, this precision is necessary for the production of modern tools or machine components in order to contribute to a significant increase in service life. We can precisely control the process with various parameters such as temperature, pressure, gas flow and voltage. This results in reproducible and customized coatings for specific applications.

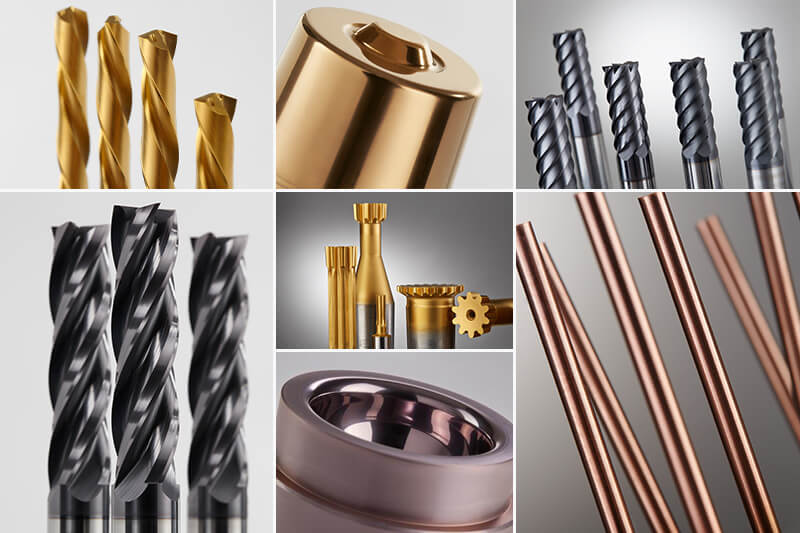

VARIETY OF MATERIALS

PVD allows the use and combination of a wide range of metals, gases and organic compounds. This flexibility allows the production of coatings with specific mechanical or tribological properties.

REDUCED ENVIRONMENTAL IMPACT

Compared to other coating processes, such as electroplating, the PVD process produces less chemical waste and requires no hazardous chemicals. This makes the process more environmentally friendly and safer for the people who work with the equipment on a daily basis. In addition, many tools can be decoated and recoated.

INNOVATION POTENTIAL

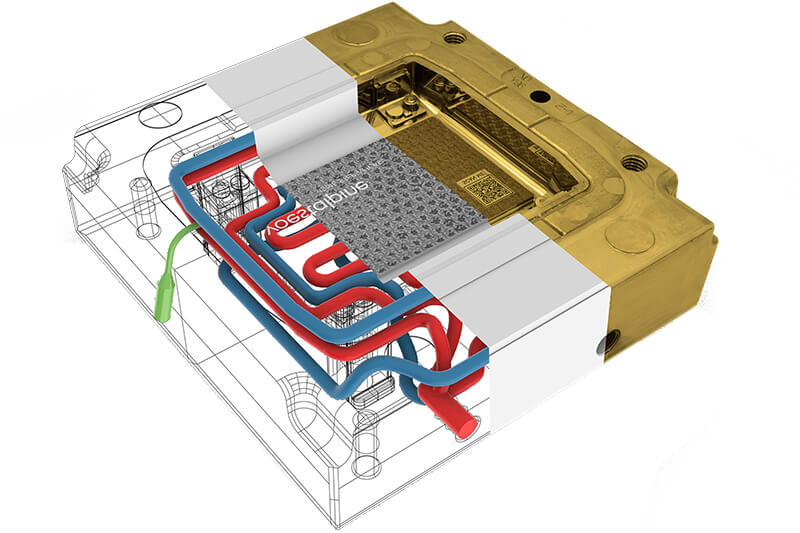

The PVD process is constantly opening up new possibilities for the development of innovative materials and coatings that are used in high-tech tools. In addition, the coating can be profitably combined with other modern production processes such as 3D printing or laser texturing.

CHALLENGES IN SCALING

Another fascinating element is the challenge of scaling up the PVD process from the development plant to industrial mass production while maintaining the quality and properties of the coatings.

VARIETY OF APPLICATIONS

PVD coatings can be found in almost all industries, including microelectronics, the automotive industry, optics, toolmaking and even medicine. This wide range of applications makes the process particularly interesting and relevant.

TECHNOLOGICAL COMPLEXITY

The PVD process is technically complex and requires a deep understanding of the physical and chemical principles that take place during coating deposition. This challenges the knowledge and skills of a process engineer and makes the process exciting time and time again.