Technology, process engineering, analytics and performance tests are the four pillars of our holistic approach to PVD development. Innovative coating solutions become possible when these four pillars are perfectly coordinated.

TECHNOLOGY

- The eifeler-Vacotec dual source technology with very high plasma activation allows fast deposition of nano-structured and multi-layered coatings with high density and excellent wear resistance.

- Our multiple arc sources concept offers the possibility to produce PVD films with up to 4 different cathode materials at a very high deposition rate.

- Our open user interface allows flexible recipe customization and development options for your processes.

PROCESS ENGINEERING

- Our development engineers have mastered the intricate handling of the smallest building blocks of matter that are produced in a PVD system.

- They guide these tiny particles precisely through the vacuum and direct them to the surface of the workpiece, where they settle in a layer.

- Every process step is precisely calculated, every gas and every flow exactly coordinated – a precise interplay of material science and physics.

- However, we not only understand which materials ensure an optimum coating, but also which damage mechanisms are at work in a wide variety of applications. Only through this holistic understanding can new solutions be developed that set new standards in terms of service life.

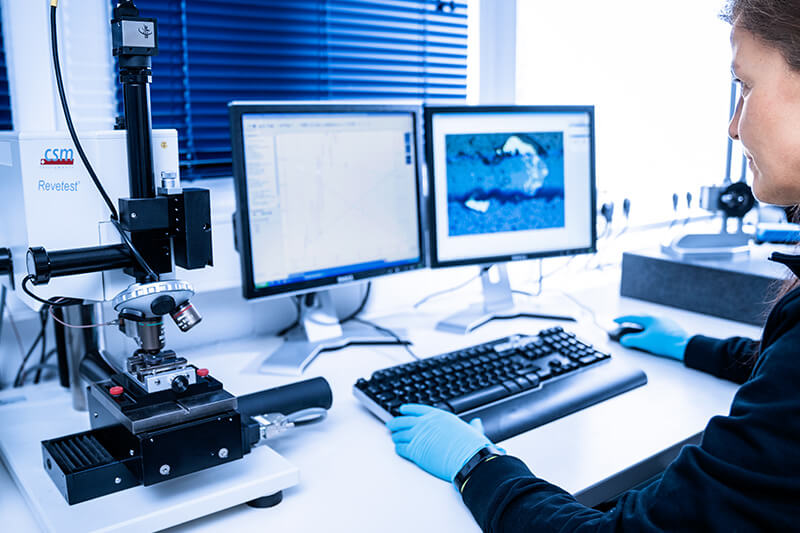

ANALYTICS

- Precision meets innovation: Our state-of-the-art analytical laboratory environment is specially designed to examine the quality and properties of PVD coatings at the highest level.

- Our advanced equipment enables us to carry out comprehensive analyses that leave no questions unanswered:

- By combining hardness measurement, coating thickness determination, optical microscopy, tribometers, confocal microscopy and SEM, we are able to provide a precise and comprehensive picture of the quality and performance of your PVD coatings.

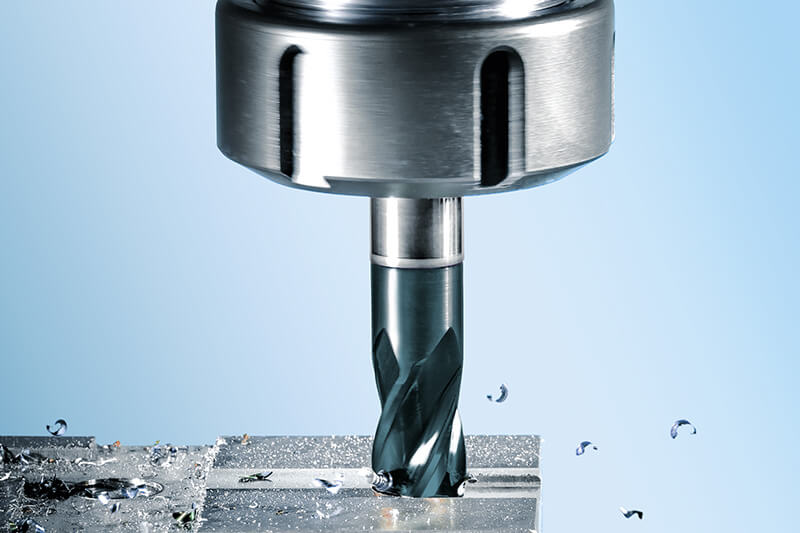

PERFORMANCE TESTS

- After development, we subject the tools and components to strict performance tests to ensure the durability and functionality of the PVD coatings under real conditions.

- We work closely with renowned institutes and university partners to ensure that our tests meet the latest scientific standards.

- These tests enable us to ensure that our coatings retain their performance even under extreme and application-related conditions.

- We therefore guarantee you products that are just as convincing in practice as they are in our R&D.