DUPLEX TECHNOLOGY

- High contact pressures, higher temperatures, increased friction and shear forces lead to new requirements on tool surface protection. An effective way to increase resistance against deformation at high contact pressures is to enhance the substrate surface hardness by plasma nitriding.

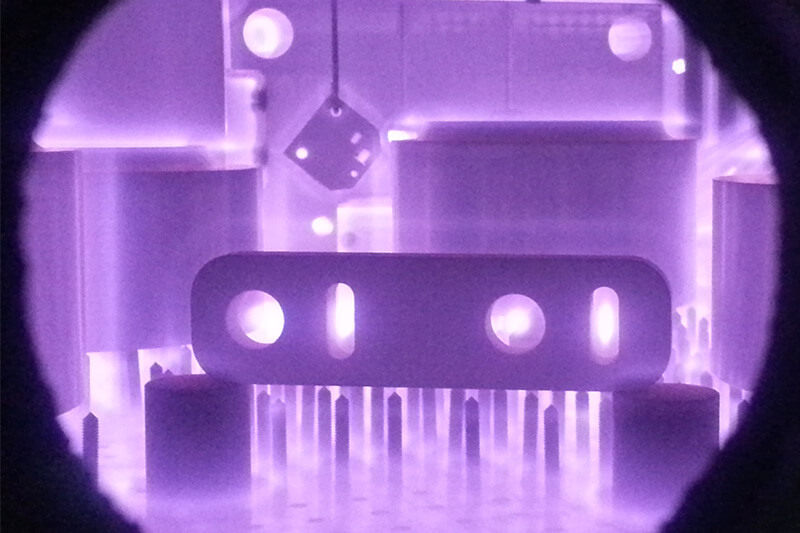

- Characteristics: Combination of in-situ plasma nitriding (50 pum depth) and PVD coating. Advantages: – Only 1 x polishing, 1 x cleaning, 1 x heating

SPCS TECHNOLOGY

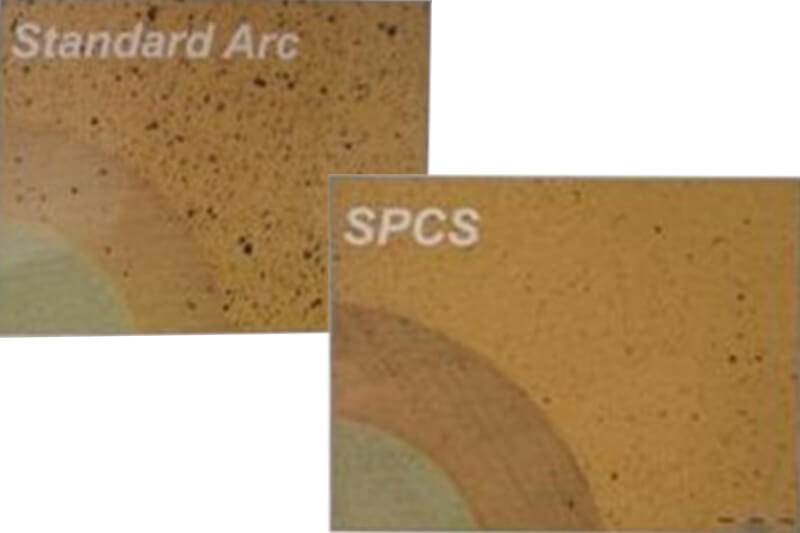

- The Strongly Poisoned Cathode Surface (SPCS) technology is based on a special arc source design providing strong poisoning of the cathode surface and high plasma activation resulting in smooth and dense coatings.

- It was developed to minimize the number of coating defects (especially droplets). This results in smoother coating surfaces compared to conventional ARC coatings.

- Vaporization of ceramics with a high melting point is possible

- Higher emission of multiply charged ions/higher degree of activation of N2 molecules.

FURTHER ADD-ONS

- Target Shutter System to avoid contamination of the targets, thereby increasing the efficiency of the processes.

- Fast Cooling System to increase the cooling rate in order to generate shorter process times and maximize the degree of utilization.

- Split Frame for flexible installation of the PVD system in confined production facilities.