MOLDADUR®-P

MOLDADUR®-P Coating – Scratch protection for sensitive surfaces

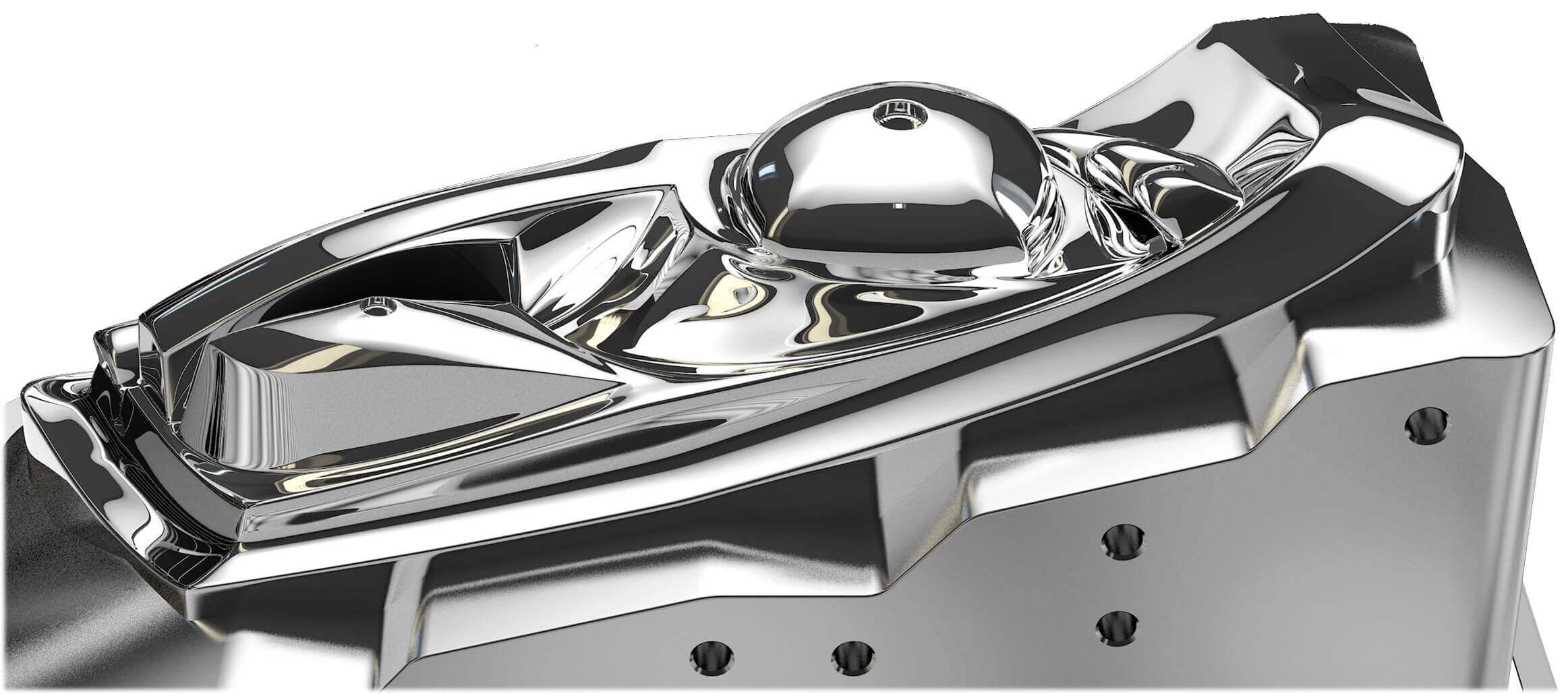

The protective layer for polished and structured surfaces in plastic mold construction.

MOLDADUR®-P is a special plasma process of voestalpine eifeler Coatings, which creates a protective layer on highly sensitive surfaces. The surface is thereby lastingly protected against wear or damage. Suitable for polished and structured surfaces on plastic molds.

MOLDADUR®-P creates a scratch-resistant surface without altering the surface quality and while preserving the visual appearance. MOLDADUR®-P, compared to conventional processes, is able to very uniformly copy the surface contours – even within depressions – while also creating a constant surface hardness on the entire tool. This is achieved primarily through the perfectly adapted process management in small systems (max. component size of Ø 33.4646″ x 31.4961″ (Ø 850 x 800 mm).

APPLICATIONS

| Treatable steels / surface hardness | All common tool steels with tempering temperatures ≥ 380 °C are treatable; the achievable surface hardness is dependent on the alloy composition of the steel. The properties of corrosion-resistant steels are preserved with MOLDADUR®-P. |

| Treatable steels | All metallically bright steel surfaces are treatable with MOLDADUR®-P, for example dash-polished, structure-polished, or high-gloss polished tools. A high-gloss polished surface is a very good precondition in this case. After the surface treatment, a repolishing is possible. |

| Treatment temperature | The treatment temperature lies in the range of 380 °C to 470 °C, depending on the material. |

PRODUCT FEATURES

- Protection against scratches and wear

- Uniform increases of surface hardness

- Weldable

- Coatable

- No changes in dimensions